Products

Apart from complete realisation of complex plant solutions for the chemical and petrochemical industry, we have developed our own products which can be individually modified and can be optimally integrated into existing systems. We also offer many of these products to you as modular and scalable Skid components which offer varied advantages.

Pre-assembly in Germany, pre-testing under real operating conditions and compact transport sizes mean high quality, quickly ready for operation and lower transport costs.

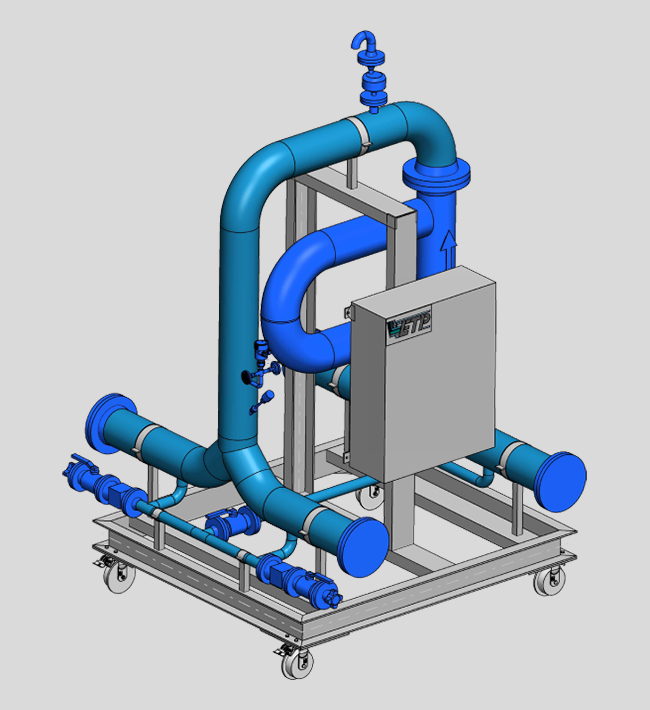

Prover

The Prover is a calibrated measuring device that is used for recalibrating on loading facilities. The Prover serves to check flow meters in an on spot loading facility with rail cars filled with light and dark oil products. The Prover is pushed on rollers to the flow meter to be checked using rails on the loading platform and connected to the pipeline using the corrugated pipe compensator.

| Dimensions: | H ~ 3 m B 1,8 m L 2,2 m |

|---|---|

| Weight: | ~ 2.250 kg |

| Mass measuring device: | Typ: CMFHC2 |

| Mass measuring device: | up to 600 m 3/ h |

| Accuracy Mass measurement: Density measurement: | ± 0,05% ± 0,0005 g/cc |

| Reproducibility Mass measurement: Density measurement: | ± 0,0025% ± 0,0002 g/cc |

| Connection pipe: | DN 200 |

| Liquid: | Masut, Diesel, Flugkraftstoff, Benzine |

| Design pressure: | 16 bar |

| Testing pressure: | 24 bar |

| Operating temperature: | -60 °C bis +55 °C |

| Certification: | Russia |

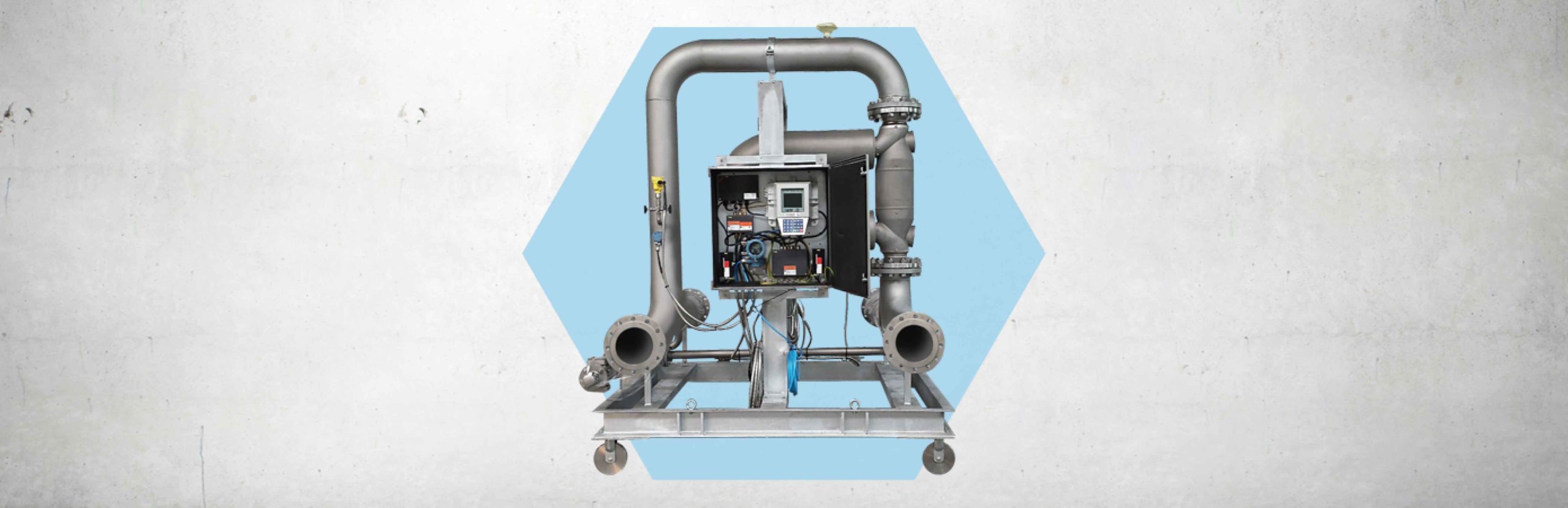

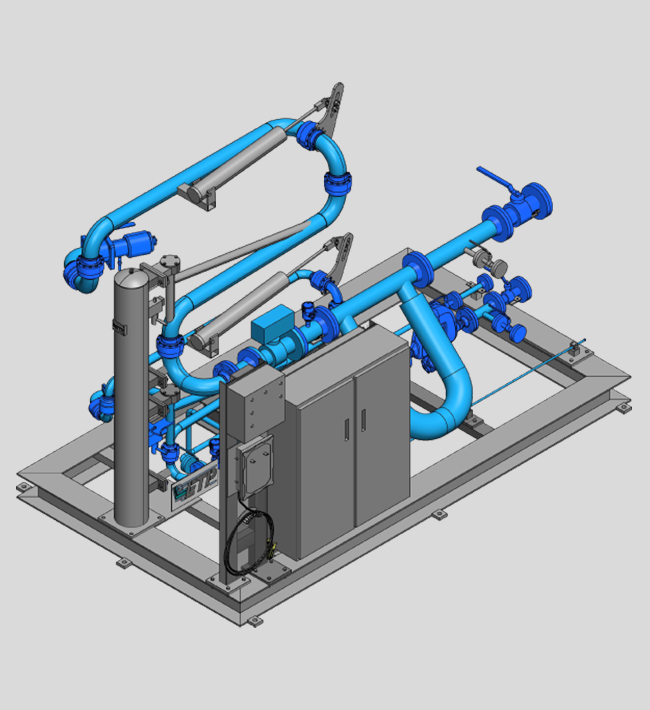

Skid bottom loading

We have developed the bottom loading Skid especially for LPG liquid loading in road tankers for any facility. Through its compact design it is easy to transport and can be set up individually. Fixing to the ground is made with durable shear connectors. A solid base framework and a balanced weight distribution also ensure larger loading radii without problems. With extensive measuring techniques and a special analysis of the control engineering, the liquid portion of the returned gas volume is extracted from the mass of the loaded product. In this way more exact data of the actual loaded liquid gas volume is obtained. We can modify the bottom loading Skid to any connection and requirement situation and therefore we can implement individual customer wishes at short notice.

| Dimensions: | H 3,5 m B 2,0 m L 2,2 m |

|---|---|

| Weight: | ~ 2.100 kg |

| Measuring principle: | Coriolis (Mass) |

| Volume flow rate: | up to 40 m3/h |

| Accuracy of the measurement: | ± 0,1% |

| Nominal sizes: | DN50 to DN80 |

| Liquid: | LPG |

| Design pressure: | PN 25 |

| Testing pressure: | 32 bar |

| Operating temperature: | -60 °C to +55 °C |

| Certification: | Russia |

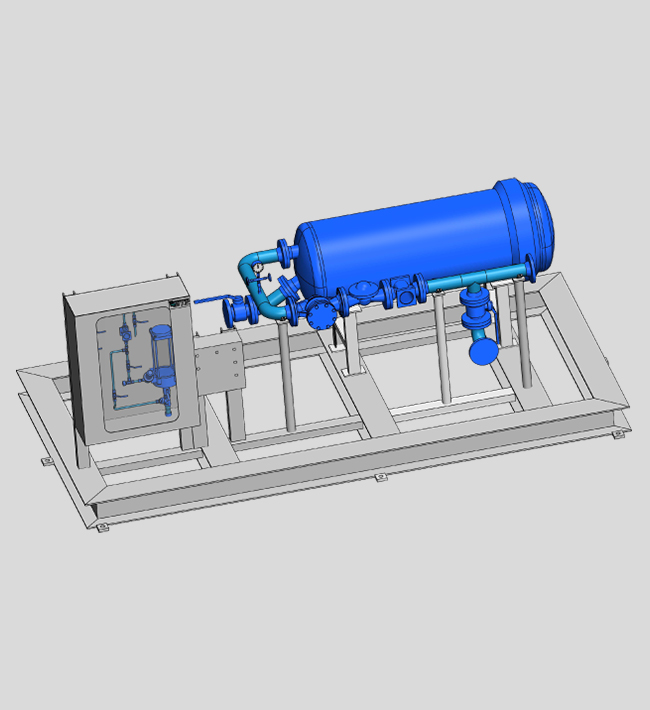

Skid aircraft fuelling

Refuller loading skid, filter Skid and pump Skid

We have designed the aircraft fuelling Skid especially for loading airfield road tankers and aircraft. Through the compact design they are easy to transport and used individually. They include filtration technology required by international regulations and the possibility to take samples. We can easily modify the Skids to customer requirements.

| Dimensions: | H -3 m B 1,6 m L 2,0 m |

|---|---|

| Weight: | ~ 3.500 kg |

| Volume flow rate: | up to 30 m3/h up to 250 m3/h |

| Accuracy Mass measurement: Density measurement: | ± 0,1% ± 0,0005 g/cc |

| Reproducibility Mass measurement: | ± 0,0025% |

| Nominal size: | Individual |

| Liquid: | Jet – A1 |

| Design pressure: | 16 bar |

| Testing pressure: | 24 bar |

| Operating temperature: | -60 °C to +55 °C |

| Certification: | Russia |

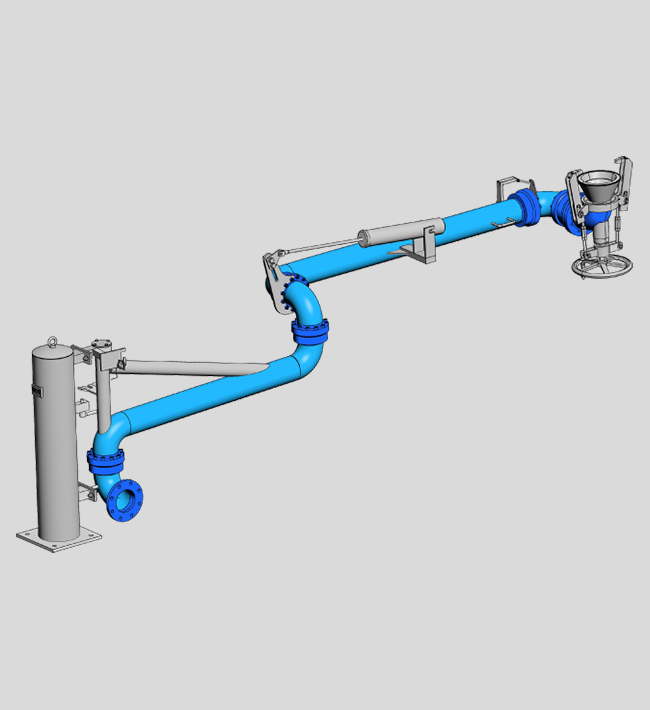

Loading arm

for LPG as well as light and dark oil products

Loading arms can be used not only for open but also closed loading and discharging of road tankers as well as rail cars. The product portfolio of ETP includes top and bottom loading arms which we can modify to almost any requirement. To complement the loading facility we can supply steel elements, such as platforms and folding stairs. The smart and slim design ensures on the one hand safe and easy handling directly at the facility and on the other hand allows quick maintenance. Compliance to international standards guarantees efficiency and safety of our loading arms. Just like other tests, such as pressure and X-ray testing. The complete equipment is produced in explosion proof design. We can also automise the loading arm with suitable sensors.

| Products: | liquid and gaseous fluids |

|---|---|

| Dimensions: | Dimensions according to the customers wishes modified to the requirements of the plant |

| Nominal sizes: | from DN25 to DN200 |

| Operating pressure: | up to 50 bar |

| Weight balance: | Spring tension cylinder Pneumatic cylinder Counterbalance |

| Operating temperature: | -180 °C to +250 °C |

| Certification: | Russia |